Technology

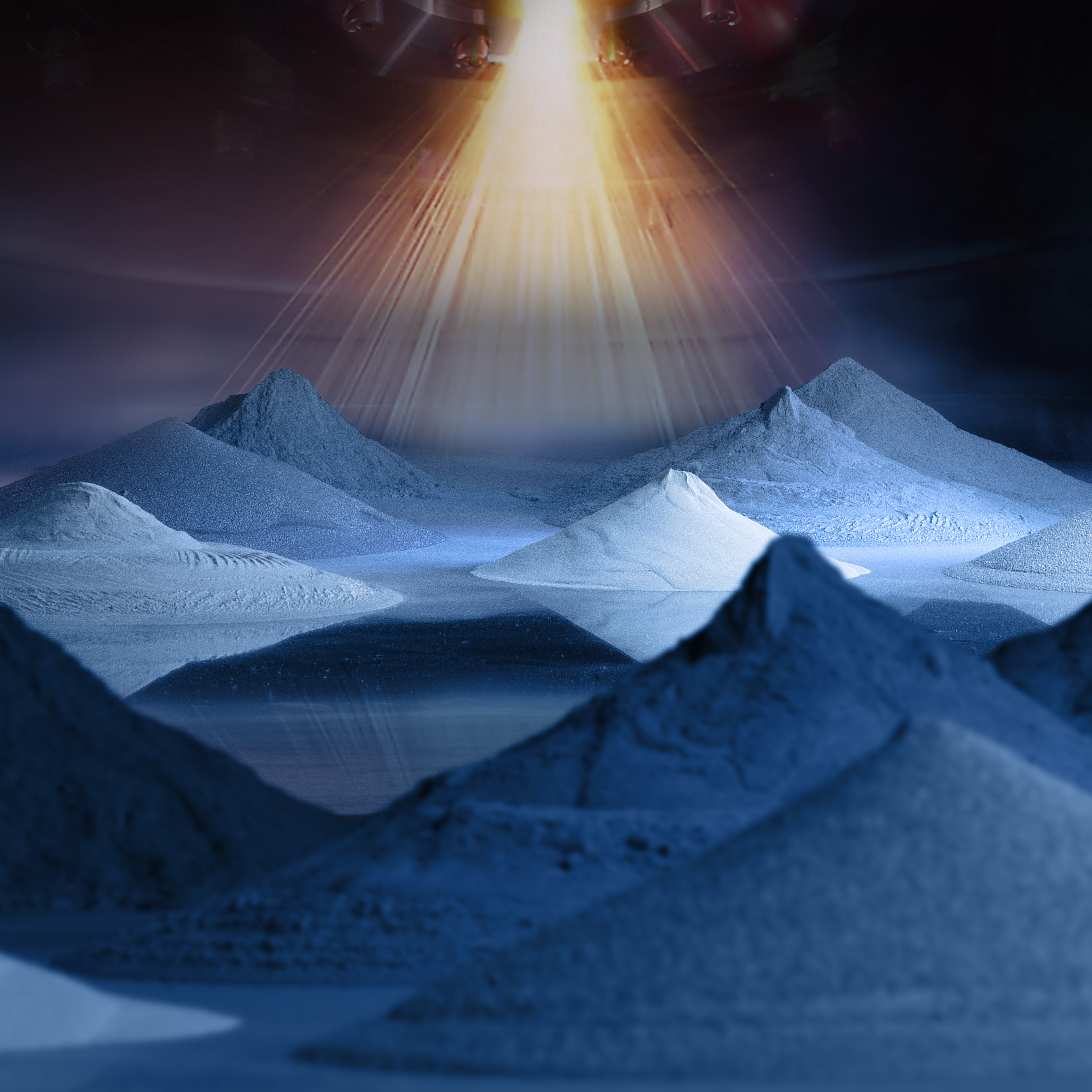

Melting and casting using the lost wax technique is one of the oldest crafts of mankind..

The first knowledge of metal extraction and processing dates back to around 8000 BC. Dated to 4500 – 3500 BC, the first purpose-designed melting furnaces existed in the Copper Stone Age. Even then, the "casters" made use of basic physical laws and chemical processes - with the simplest of means.

We don't even want to imagine the difficulties our early ancestors had to contend with, the setbacks they had to put up with and how many attempts it took to cast a handsome piece of jewellery, an ax or a blade.

Despite thousands of years of experience and highly developed technical possibilities, good investment casting results still often pose a challenge today. Nobody can afford the "trial and error" principle of the past.

Casting quality that can be achieved quickly, replicated and certified is required. Our claim and development principle is therefore: to offer casting technology that is quick and easy to master, that works reliably and that ensures first-class results.

Tailor-made: When we founded Indutherm in 1996, we questioned everything we knew about current investment casting technology. The systems that were on the market at the time were often too complicated, made up of too many and sometimes oversized purchased components, and were therefore too expensive and too vulnerable. Our strategy was to develop the essential elements of our technology ourselves. Our first casting machines were simple but thoroughly engineered, with induction generators we developed ourselves, tailored to the needs of our first target group, the jewelry industry. As a result, our systems were not only better, but also cheaper than those of our competitors..

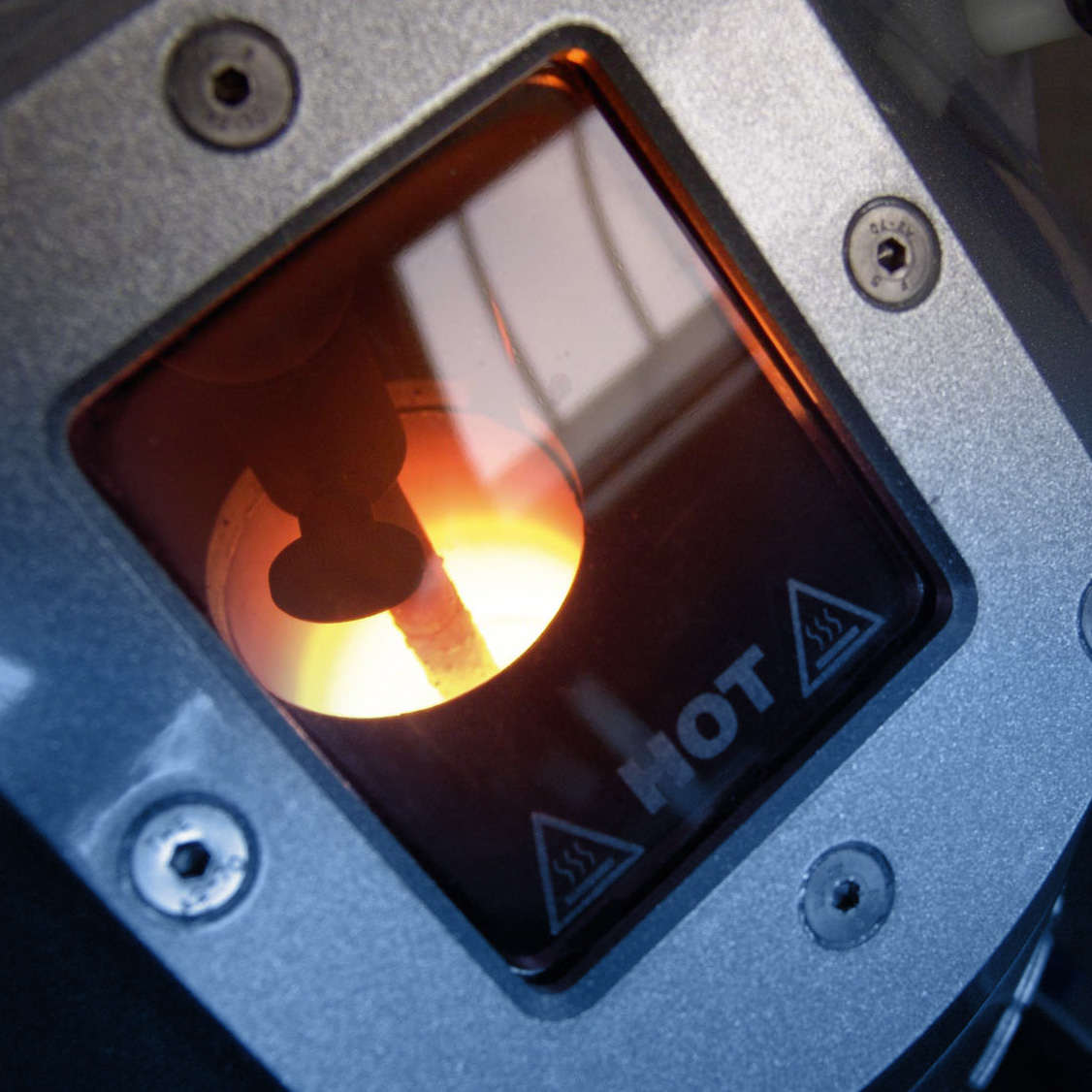

High-tech on skater rollers: With our compact table casting systems, we were able to drastically reduce the number of moving parts and mechanical components and thus the acquisition and maintenance costs with a trick: the entire heating, control and casting technology is rotated together for casting - in style on skater wheels in a "half pipe".

Vibration technology for optimized mold filling. We didn't invent casting under vibration. But we were the first to develop vibration technology for investment casting and put it into series production. Our vibration casting process received the MJSA award in the USA in 2006 and has since gained widespread acceptance, especially over centrifugal casting, which had previously been the leader in platinum casting, but was more expensive and more fragile.

Titanium casting made inexpensive. In a research project funded by the Federal Ministry of Economics and Technology, we were able to bring a high-temperature casting system for highly reactive metals onto the market through clever evacuation technology in combination with specially developed melting crucibles, which costs only a fraction of previous titanium casting systems and is therefore completely new for many industries production possibilities opened up.

Research

Our way to new technologies

Projects that advance our customers

Industry 4.0

We are ready!

Discover how easy and how profitable you can digitalize your processes with our DMS solutions!

Induction Technology

Our choice from the beginning

Why induction heating is the best way to melt metal.

Energy Efficiency

Energy efficiency that goes further

Read how you can save up to 50% energy with our efficiency concept.

Vacuum Pressure Casting

A suitable solution for every investment casting

Find out more about how it works and the possibilities!

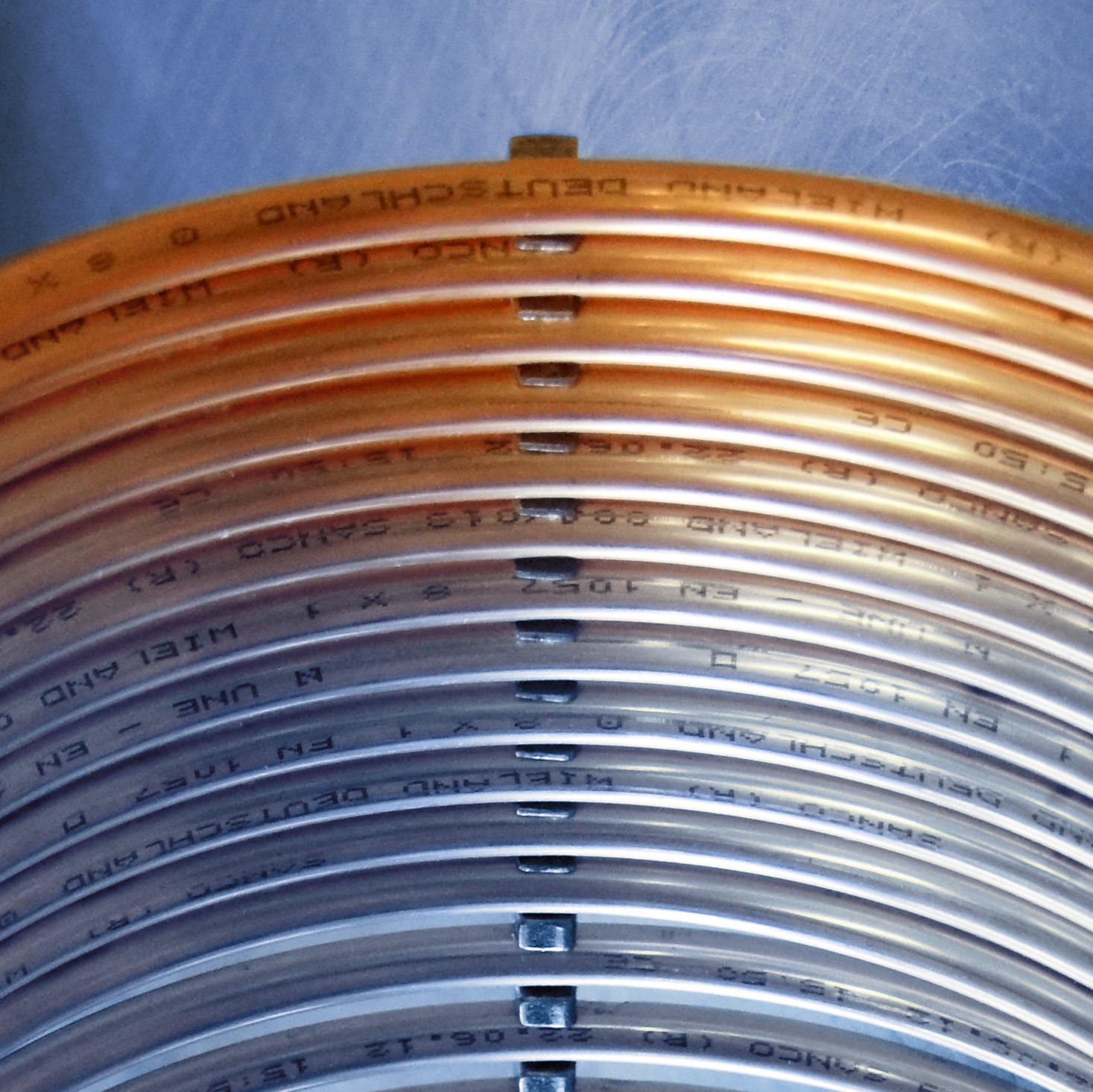

Continuous Casting

Always the best wire!

First-class semi-finished products in almost any shape - discover our "Multitools"!

Recycling Melting

A science in itself

Why it sometimes has to be an open furnace...

Vibration Technology

Good Vibrations!

Discover how significantly vibration can improve your casting results!

Sintering / Diffusion Welding

The dream wedding of gold and silver!

How you create permanent connections with the highest precision.

You can find us here!

Through clicking of this button the site will connect to the Open Street Maps - Servers. More at "Open Street Maps" on our Privacy Page.